Premium Stainless Steel Seamless Pipes

We manufacture high-integrity stainless steel seamless pipes engineered for demanding pressure applications, superior corrosion resistance, and structural reliability. Leverage Kun Metal's 30+ years of expertise for critical fluid and gas transport systems worldwide.

The Kun Metal Seamless Advantage

Stainless steel seamless pipes offer distinct advantages over welded alternatives in critical applications:

Seamless Pipe Grades and International Standards

We supply stainless steel seamless pipes in various grades to meet specific application requirements, adhering to key international standards:

Manufacturing Process

Our stainless steel seamless pipes are produced using advanced methods ensuring superior quality:

Hot Piercing / Extrusion

Solid billets are heated and pierced or extruded to form a hollow shell, creating the fundamental seamless structure.

Cold Drawing / Cold Rolling:

The hollow shell is further processed (often multiple times with annealing in between) to achieve precise dimensions, improved surface finish, and enhanced mechanical properties.

Heat Treatment:

Controlled annealing (solution annealing) is performed to relieve stresses, optimize corrosion resistance, and ensure the required material properties.

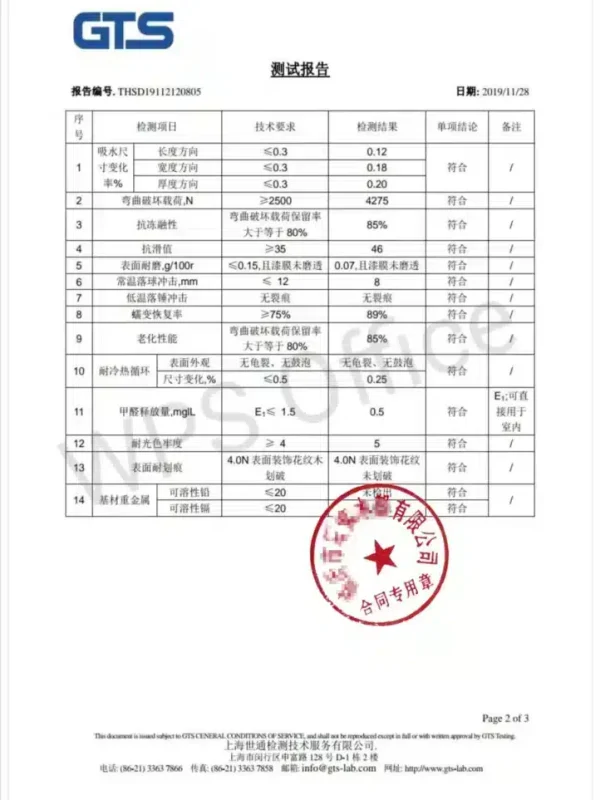

Quality Assurance & Testing

Stringent quality control and testing procedures guarantee the integrity of every pipe:

Non-Destructive Testing (NDT)

Includes Ultrasonic Testing (UT) and/or Eddy Current Testing (ET) to detect potential flaws without damaging the pipe.

Hydrostatic Testing

Each pipe is pressure tested with water to verify its ability to withstand operating pressures without leakage.

Dimensional & Visual Inspections

Thorough checks for Outer Diameter (OD), Wall Thickness (WT), length, straightness, and surface finish against specified tolerances.

Mechanical & Chemical Testing

Includes tensile tests, hardness tests, flattening tests, flare tests, and chemical composition analysis (Spectro) as per standard requirements.

Critical Applications Relying on Seamless Integrity

Kun Metal's stainless steel seamless pipes are the trusted choice for demanding industries including:

Oil & Gas (Upstream & Downstream)

Pipelines, processing lines, control lines, downhole tubing.

Chemical & Petrochemical Processing

Transporting corrosive fluids and gases, reactors, process piping.

Power Generation (incl. Nuclear)

Boiler tubes, superheaters, feedwater heaters, condenser tubes.

Heat Exchangers & Condensers

Efficient heat transfer applications requiring high integrity.

Shipbuilding & Aerospace

Applications requiring high strength-to-weight ratio and reliability.

Certified Quality, Delivered Globally

Quality is paramount at Kun Metal. Our manufacturing processes adhere to ISO 9001:2008 and relevant industry certifications (e.g., PED, ASME). We combine this certified quality with 30+ years of manufacturing experience, competitive pricing, and a reliable global logistics network to deliver superior stainless steel seamless pipes on time, anywhere in the world. Trust us for your critical projects.

Specify Your Stainless Steel Seamless Pipe Needs

Partner with Kun Metal for high-performance stainless steel seamless pipes manufactured to your exact specifications. We offer a wide range of grades, sizes, and lengths, with comprehensive testing and certifications.

Contact our expert sales team today to:

- Discuss your technical requirements

- Request Material Test Certificates (MTCs)

- Get a competitive quote for your project

Request A Quote

We are ready to answer right now!